Remote or temporary camps, whether set up for disaster relief, exploration, or construction, face unique challenges […]

More smoke along with various other pollutants are introduced right into the air throughout the ‘‘ […]

Environmentally Friendly Top Loading Incinerators for Hospitals: A Comprehensive Solution by HICLOVER In today’s healthcare environment, […]

Gasified incineration for burning clinical wastes. Gas kind: Natural Gas Burning Capacity: –– 30-50 kg/time –– […]

The Incinerator Plant is output wastes incineration from Different petrochemical units. In this project we want […]

Items/Model TS50M Picture Burn Rate Average 50 kg/hour Feed Capacity Average 50-150 per feeding Control […]

Model YD-100 Picture Burning Rate 100-150 kgs/hour Primary Combustion Chamber 2000 Liters Secondary Combustion Chamber 500 […]

Incinerator testing fire in factory. The secondary chamber burn first and now what you see is […]

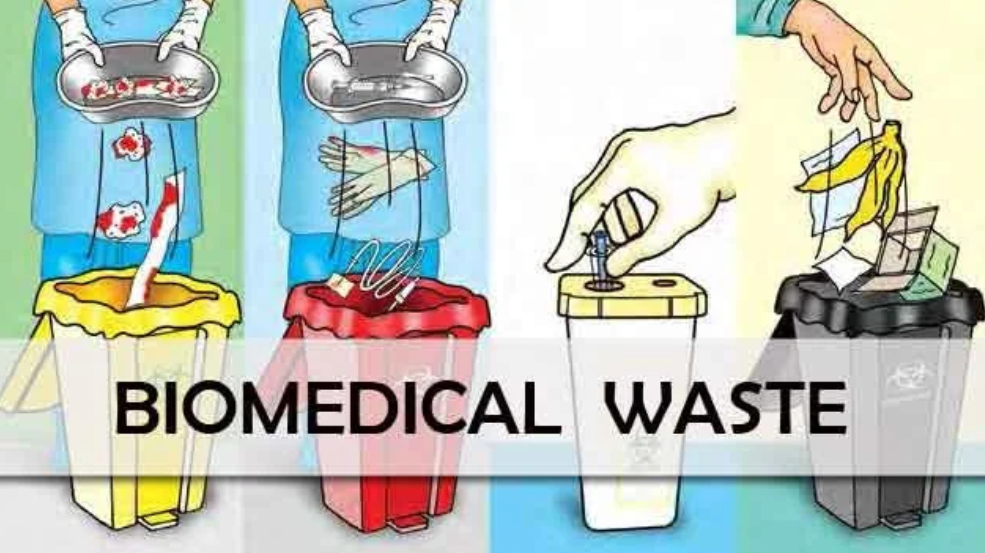

Biomedical waste refers to any solid or liquid waste generated from medical, biological, or research activities […]

Medical Waste Incinerator, 50 to 60 Kg/hrSupport Health Sector Support ProjectPoint of Installation (Hospitals) Moi Voi, Makindu, Maragua, Eldama Ravine and Isiolo District Hospitals1. General DescriptionSupply, delivery, installation and commissioning of a medical waste incinerator suitable for disposal of Medical, General and Pathological waste in a safe and clean environment. The unit shall consist of two chambers and operate on the principal of controlled air and temperature. The unit shall consist a particulate remover (scrubbers) as stipulated in waste management regulations, 2006 (Legal notice NO. 121 of 29th September, 2006). The Unit shall be fully automatic and controlled by an automatic electronic controlled system except loading system which shall be manual. The unit shall be capable of incinerating between 50 to 60 kg of solid medical waste per hour. It shall be constructed from mild or aluminized steel lined with refractory material.Main unit Application For incineration, general and pathologicalCapacity 50 C 60 kg/h burn rateType Two combustion chambers type; primary and Secondary, controlled/forced combustion air type with a flue gas emission scrubbing unitOperating time Minimum 8 hours dailyOperating temperature From 850 0C to 1200 0C, Automatic controlledResidual Ash 5 to 10% 3.2 Primary ChamberConstruction Constructed from heavy duty mild or aluminized steel Orequal and approved equivalentInsulation material Refractory material lining similar or equal to calcium Silicate and hot face combination of heavy duty brickworkInternal Construction Fixed hearth type complete with gratings, concave bottomand charging door, lined with refractory materialCharging Door Suitable for manual loading of wastes and with smooth Dear seal equivalent of Ceramic seals with hinges.Door Lock Automatic, Electric typeAsh removal door Provided, for removing resultant bottom ash leftovers from the Primary chamberGratings […]