Mobile Incinerator for Remote Camps: Your Essential Waste Management Solution

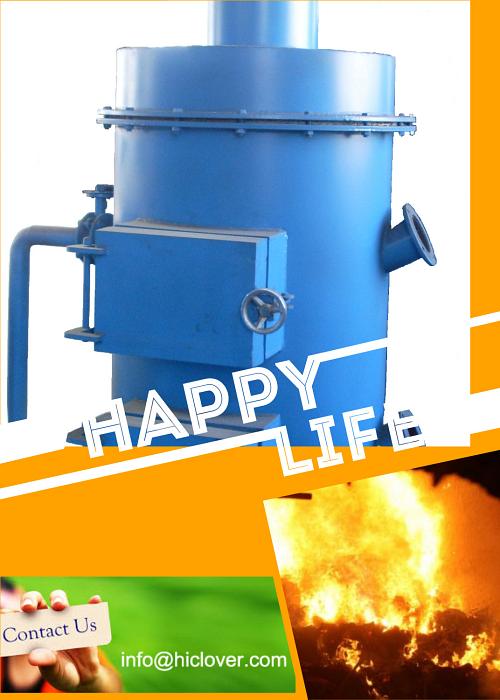

In remote camps and temporary installations―whether at crisis management sites, refugee camps, or remote research stations―effective waste management is a critical challenge. Mobile Incinerator for Remote Camps offers an innovative, portable solution to safely dispose of waste while ensuring minimal environmental impact. At Hiclover, we manufacture a wide range of incinerators, including containerized mobile, top loading, automatic, medical, animal, pets cremation, and other solid waste incinerators. Our products feature advanced options such as diesel, natural gas, and LPG fuel types, optional wet scrubber systems, Italy brand burners, PLC control systems, multiple combustion chambers, and heat recovery functions.

1. The Remote Camp Challenge

Remote camps―whether set up for oil fields, UN/WHO operations, military camps, or temporary infrastructure projects―often lack permanent waste disposal systems. Accumulated waste can become a health hazard and contribute to environmental degradation. In these contexts, a Mobile Incinerator for Remote Camps plays a pivotal role in:

- Rapid Deployment: Easily transported to any remote location.

- Efficient Waste Reduction: Quickly reduces large volumes of waste.

- Environmental Protection: Incorporates advanced emission control systems to minimize pollutants.

This specialized solution is designed to operate under challenging conditions where conventional waste management systems simply cannot reach.

2. Key Technical Features and Optional Configurations

Our mobile incinerators are engineered to meet diverse operational demands. Here are some of the standout features and customizable options:

- Fuel Type Flexibility: Choose from Diesel, Natural Gas, or LPG based on availability and environmental regulations.

- Feeding Door Options: Available with side, front, or top feeding doors to ensure compatibility with various waste types.

- Smoke Scrubber Systems: Options for both dry scrubber and wet scrubber systems help control emissions effectively.

- Burning Rate & Chamber Size: Designed to achieve burning rates from around 5kgs to 1000kgs per hour. Combustion chambers are available in sizes from 100 Liters to 6000 Liters, catering to both small and large-scale operations.

- Versatile Deployment: Our incinerators come in containerized, trailer, and sledge types, making them highly adaptable for mobile use.

- Advanced Control Systems: Featuring PLC Automatic Control Mode, intelligent sensors for continuous feeding with worker protection, and High Temperature Retention (HTR) with adjustable settings.

- Safety and Monitoring: Equipped with intelligent save fuel function, temperature monitors, corundum probe tubes (up to 1400℃), temperature protection, automatic cooling, and automatic false alarm systems (display, voice, and light). Additionally, systems such as the Automatic Protection Operator (APO), system testing models, time settings, and LCD display progress bars further ensure reliable operation.

- Supportive Infrastructure: Integrated oil tanks and oil tank stands enhance operational efficiency. Spare parts and PPE are also available to maintain long-term functionality.

These technical attributes ensure that our Mobile Incinerator for Remote Camps not only meets but exceeds the rigorous demands of waste management in remote and temporary setups.

3. Real-World Applications and Global Impact

Our incinerators are trusted by customers around the globe. They are deployed in various remote settings including:

- Crisis Management Sites & Refugee Camps: Providing safe waste disposal in areas where traditional systems are unavailable.

- Military & Peacekeeping Camps: Ensuring hygienic conditions and efficient waste reduction under demanding operational circumstances.

- Oil Fields & Remote Industrial Sites: Offering robust solutions that can handle both medical and solid waste.

- Infrastructure & Research Camps: Enabling sustainable waste management that supports environmental conservation.

Clients from regions such as Afghanistan, Somalia, Oman, East Timor, Ethiopia, Mauritius, Pakistan, Papua New Guinea, Burundi, Australia, Germany, Indonesia, UAE, Kenya, and many other countries have successfully implemented our mobile incinerators. International organizations, including the United Nations and World Bank, have also recognized our technology for its reliability and efficiency.

4. Why Hiclover?

At Hiclover, our commitment to innovation, quality, and sustainability drives everything we do. Choosing our Mobile Incinerator for Remote Camps means:

- Reliability: Engineered for optimal performance in the most challenging environments.

- Flexibility: Customizable features allow you to tailor the system to your specific waste management needs.

- Safety: Advanced controls and monitoring systems ensure safe operation for both workers and the environment.

- Global Support: With a worldwide customer base and dedicated technical service, we’re ready to support your project wherever it may be.

For organizations needing robust, mobile waste management solutions, our incinerators are the smart choice. We transform waste challenges into opportunities for environmental sustainability and operational efficiency.

5. Get in Touch

Ready to equip your remote camp with a cutting-edge waste management solution? Hiclover is here to help. Contact us for more details about our Mobile Incinerator for Remote Camps:

- Website: www.hiclover.com

- Call/WhatsApp: +86-13813931455

- Email: sales@hiclover.com | hicloversales@gmail.com

- Send a Simple Message: Click Here

- General Technical/Commerce Requirements: Submit Your RFQ

Conclusion

Waste management in remote camps demands flexibility, efficiency, and reliability. With Hiclover’s Mobile Incinerator for Remote Camps, you gain a robust, adaptable solution that meets these challenges head-on―ensuring safe disposal, energy recovery, and environmental protection in even the most isolated locations. Embrace the future of waste management with Hiclover and transform your remote camp operations into a model of sustainability and innovation.

Comments are closed